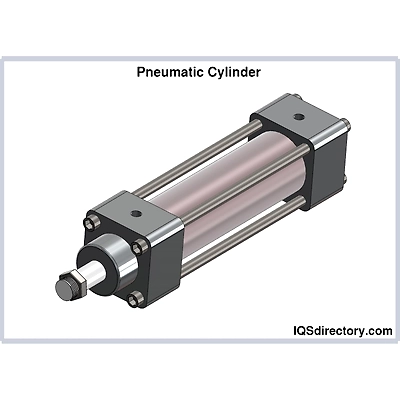

Pneumatic Air Cylinder

-

Product is not available

Country Of Origin : India

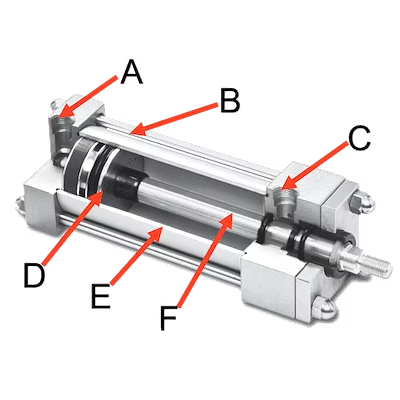

Cylinder Barrel (Tube): This is the main body of the cylinder where the air is housed. It's typically made from durable materials like aluminum or steel.

Piston: Inside the barrel, the piston is driven by the air pressure and moves back and forth. It divides the barrel into two chambers—one for the supply air and the other for the exhaust air.

Piston Rod: Attached to the piston, the piston rod extends outside the cylinder and is used to connect to whatever is being moved (a mechanical system, load, etc.).

End Caps: These are located at both ends of the cylinder and house seals and the rod guiding mechanism.

Seals: These are used to prevent air from leaking out and to ensure smooth movement of the piston.

Ports: These are openings through which air is supplied and exhausted into the cylinder. There may be multiple ports depending on the cylinder's

Types of Pneumatic Cylinders:

Single-Acting Cylinders: These only use air pressure to extend the piston in one direction. A spring is often used to return the piston back to its original position when the air supply is cut off.

Double-Acting Cylinders: These use air pressure to extend and retract the piston, meaning both directions of motion are powered by compressed air.

Rodless Cylinders: These cylinders have no piston rod. Instead, the piston moves within the cylinder, and a mechanical drive system (like a magnet or mechanical chain) is used to move the load.

Compact Cylinders: These are designed to be smaller and more space-efficient while still providing the same level of force and motion.

Applications:

Automation Systems: Pneumatic cylinders are widely used in factories and assembly lines for tasks like pushing, lifting, or moving components.

Material Handling: They’re used in robotic arms, conveyors, and lifts.

Packaging and Processing: In automated packaging machines or processing lines, pneumatic cylinders can assist in handling items.

Clamping and Pressing: Pneumatic cylinders can exert significant force to clamp, press, or hold items in place during various operations.

Advantages:

Fast Movement: Pneumatic cylinders can move quickly due to the high-speed movement of air.

Clean Operation: Compressed air doesn’t leave residue, which makes it a cleaner alternative to hydraulic systems.

Cost-Effective: Pneumatic systems tend to be cheaper and easier to maintain than hydraulic or electric alternatives.